6S series vertical shaft impact crusher is based on the original high-performance VSI series and combined with actual .....

Read More >>

Read More >>

The Shunky CS series cone crusher is designed to crush high or medium hardness material, such as iron ore, copper ore....

Read More >>

Read More >>

SKJ series European Jaw Crusher is generally suitable for primary and secondary crushing. Adopting the most advanced technology ....

Read More >>

Read More >>

European Coarse Grinding Mill

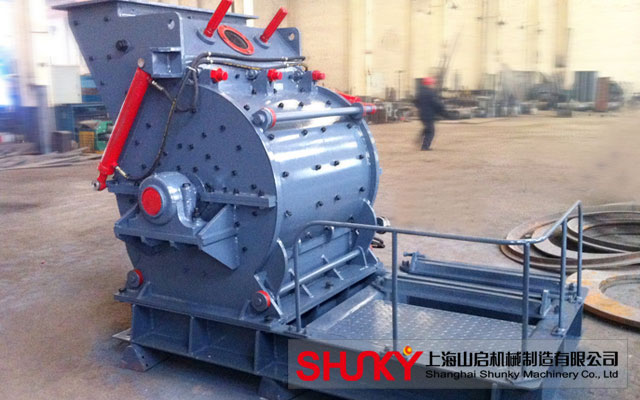

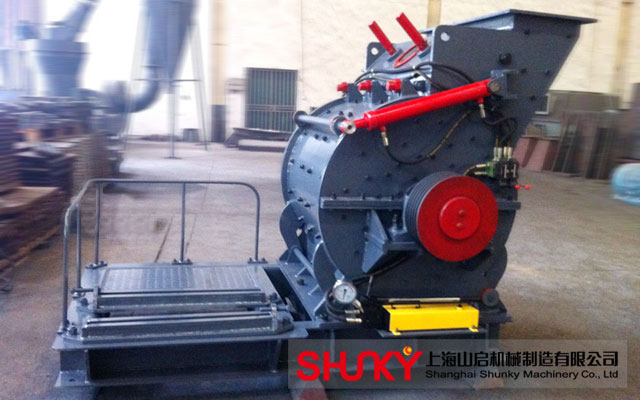

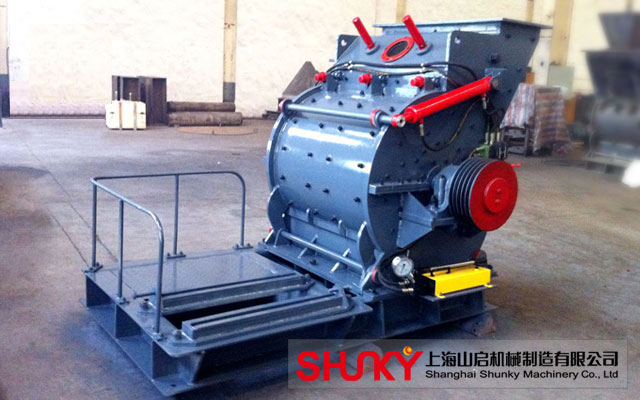

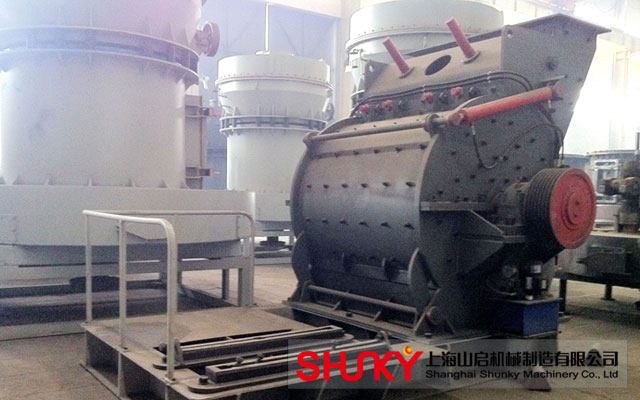

Product Description:

European Coarse Grinding Mill is widely used in metallurgy, construction, chemical and other industries, also widely used to produce concrete, limestone, raw coal, silicon carbide, gangue, sand, refractory materials and ceramic, etc. It is ideally suitable for primary, secondary and fine crushing. The largest compression resistance of all kinds of soft and hard ore to be crushed is 320 M Pa.

Working Principle:

European Coarse Grinding Mill is mainly made up of main case, rotor, impact plate and grate. The main case consists of two parts and is welded by cutting steel plates, and the others are connected with bolts. There are high manganese steel liners embedded in the main case, which is convenient to be replaced after wearing. Several uniform weight blow bars are installed on its spindle and are all tightened by highly strengthen bolts. The main engine drives spindle through motor and v-belt, which makes the rotor do movement to and fro, large rocks go into the crushing cavity from feeding opening and then be crushed by high speed moving blow bar. Crushed qualified materials are discharged from the interval between grates at the bottom, while the unqualified are still kept in the crushing cavity, crushed by rotor and blow bar repeatedly till they meet the established requirements. To avoid jams, the water content of materials to be crushed is not more than 20% generally.

European Coarse Grinding Mill is widely used in metallurgy, construction, chemical and other industries, also widely used to produce concrete, limestone, raw coal, silicon carbide, gangue, sand, refractory materials and ceramic, etc. It is ideally suitable for primary, secondary and fine crushing. The largest compression resistance of all kinds of soft and hard ore to be crushed is 320 M Pa.

Working Principle:

European Coarse Grinding Mill is mainly made up of main case, rotor, impact plate and grate. The main case consists of two parts and is welded by cutting steel plates, and the others are connected with bolts. There are high manganese steel liners embedded in the main case, which is convenient to be replaced after wearing. Several uniform weight blow bars are installed on its spindle and are all tightened by highly strengthen bolts. The main engine drives spindle through motor and v-belt, which makes the rotor do movement to and fro, large rocks go into the crushing cavity from feeding opening and then be crushed by high speed moving blow bar. Crushed qualified materials are discharged from the interval between grates at the bottom, while the unqualified are still kept in the crushing cavity, crushed by rotor and blow bar repeatedly till they meet the established requirements. To avoid jams, the water content of materials to be crushed is not more than 20% generally.

1. High productive capacity, large crushing ratio.

2. Low power consumption, cubical final product size.

3. Simple mechanical structure, compact and convenient.

4. Less investment costs, convenient to manage.