6S series vertical shaft impact crusher is based on the original high-performance VSI series and combined with actual .....

Read More >>

Read More >>

The Shunky CS series cone crusher is designed to crush high or medium hardness material, such as iron ore, copper ore....

Read More >>

Read More >>

SKJ series European Jaw Crusher is generally suitable for primary and secondary crushing. Adopting the most advanced technology ....

Read More >>

Read More >>

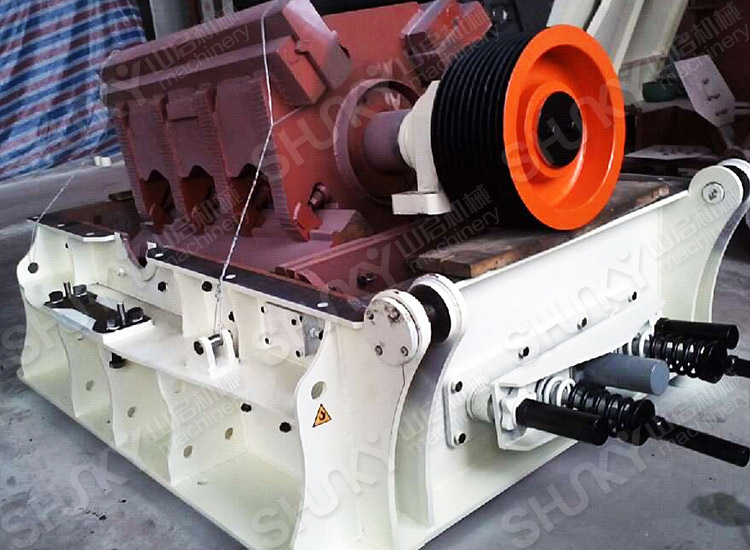

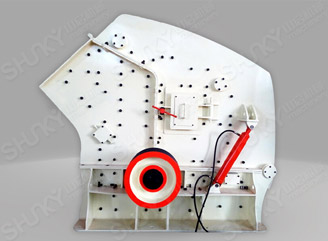

HPF Series Impact Crusher

Product Description:

HPF series hydraulic impact crusher is designed with international technology and world-class manufacturing process based on PF impact crusher. The HPF hydraulic impact crusher applies to crush hard material and ore. The maintenance and replacement of vulnerable part is easier because of the hydraulic adjustment for opening size. Three –curtain cavity design makes it perform well in the fine crushing and superfine fine crushing operation.

Working principle

When Impact crusher works, under the driving force of motor, the rotor rolls at a high speed with the blow bar on it hitting the material into pieces, and then the material will be thrown toward the impact device and then to the blow bar, so it will be crushed again. This process repeats until materials are crushed to the requested size. The product size and output can be controlled by adjusting the clearance between impact plate and blow bar. This impact crusher is designed with spring safety device,when non-crushing material enter into crushing chamber, the impact rack will recede and then the non-crushing is discharged.

HPF series hydraulic impact crusher is designed with international technology and world-class manufacturing process based on PF impact crusher. The HPF hydraulic impact crusher applies to crush hard material and ore. The maintenance and replacement of vulnerable part is easier because of the hydraulic adjustment for opening size. Three –curtain cavity design makes it perform well in the fine crushing and superfine fine crushing operation.

Working principle

When Impact crusher works, under the driving force of motor, the rotor rolls at a high speed with the blow bar on it hitting the material into pieces, and then the material will be thrown toward the impact device and then to the blow bar, so it will be crushed again. This process repeats until materials are crushed to the requested size. The product size and output can be controlled by adjusting the clearance between impact plate and blow bar. This impact crusher is designed with spring safety device,when non-crushing material enter into crushing chamber, the impact rack will recede and then the non-crushing is discharged.

1. Hydraulic device makes it easier to replace blow bar and adjust the discharging size. Wicket on frame makes it convenient for maintenance and inspection.

2. Adoption of the world-class manufacturing processes and the most high-end raw materials.

3. Integral bearing and cast steel structure, which is perfectly cooperated with rack, enhances radial strength of the bearing.

4. The special plate hammer fixtures make it more convenient for maintenance and disassembly.

5. New adjustment device shorten the time of halting and overhaul.

6. International advanced bearing, stronger carrying capacity and longer service life.

7. Strict and high standard testing method ensures reliable.

2. Adoption of the world-class manufacturing processes and the most high-end raw materials.

3. Integral bearing and cast steel structure, which is perfectly cooperated with rack, enhances radial strength of the bearing.

4. The special plate hammer fixtures make it more convenient for maintenance and disassembly.

5. New adjustment device shorten the time of halting and overhaul.

6. International advanced bearing, stronger carrying capacity and longer service life.

7. Strict and high standard testing method ensures reliable.